nozzle heaters in soudi arabia

Nozzle heaters from HeatMaster International are made to heat various industrial applications precisely and reliably. These heaters are frequently employed in procedures like plastic extrusion and injection molding that call for precise temperature control. They provide effective heat transfer and aid in preserving the ideal temperature for the best results and quality.

applications of nozzle heaters

The following are the main applications for nozzle heaters:

1. Plastic Extrusion and Injection Molding: To keep the temperature at the right level for melting and processing plastics, they heat the nozzles of extrusion and injection molding machines.

2. 3D Printing: They guarantee that the nozzle in 3D printers is heated precisely, which promotes accurate layer deposition and a smooth filament flow.

3. Food Processing: Nozzle heaters assist in regulating the temperature of food during extrusion or other processing steps in some food production operations.

4. Automotive Industry: They guarantee uniform heating for improved material flow and part quality in the manufacture of different plastic components.

benefit of using nozzle heaters from heatmaster international

Of course! The following are 10 advantages of HeatMaster International nozzle heaters:

1. Accurate Temperature Control: Provides the precise heating needed for various materials, improving process precision.

2. Enhanced Efficiency: Enhances process efficiency overall by optimizing energy consumption and lowering operating expenses.

3. Improved Heat Transfer: Increases thermal conductivity, which improves uniformity and material flow.

4. Durability: Designed to survive hard industrial environments, offering dependable operation and an extended service life.

5. Customizable Solutions: Provides specialized designs to fulfill certain application requirements while guaranteeing system compatibility.

6. Reduced Maintenance: Well-built structures require less frequent maintenance and fewer breakdowns.

7. Uniform Heating: This reduces temperature fluctuations and guarantees constant product quality by distributing heat evenly throughout the nozzle.

custom nozzle heater solution

HeatMaster International offers custom nozzle heater solutions that are made to fit particular application needs and maximize efficiency in a range of industrial operations. Here are a few crucial elements:

Tailored Design: To ensure a precise fit and effective heat distribution, custom heaters are designed to meet the exact size and requirements of your nozzle.

Optimized Performance: These heaters, which are made for certain uses, improve process control and thermal efficiency, which raises the standard of the final product.

Material Compatibility: Materials used in custom solutions are appropriate for the operating and environmental conditions of the application, including corrosive or high temperatures.

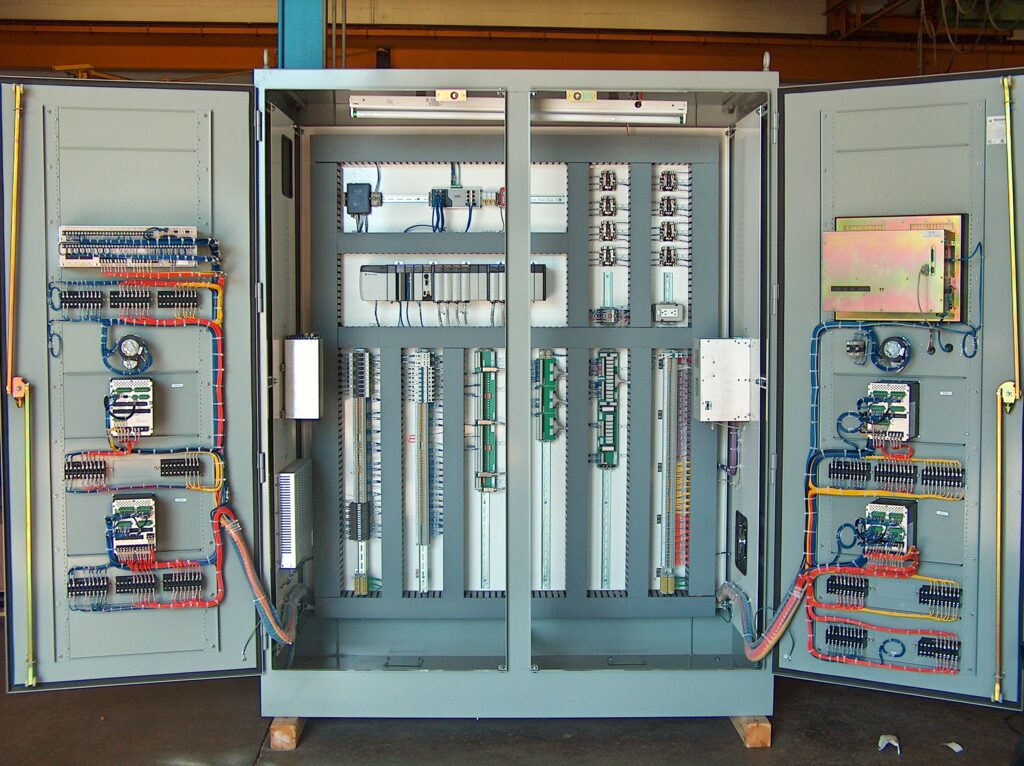

Temperature Control: To ensure constant heating and adjust to process variations, features like exact temperature regulation and control systems may be included.