Industrial Continuous Heating Systems

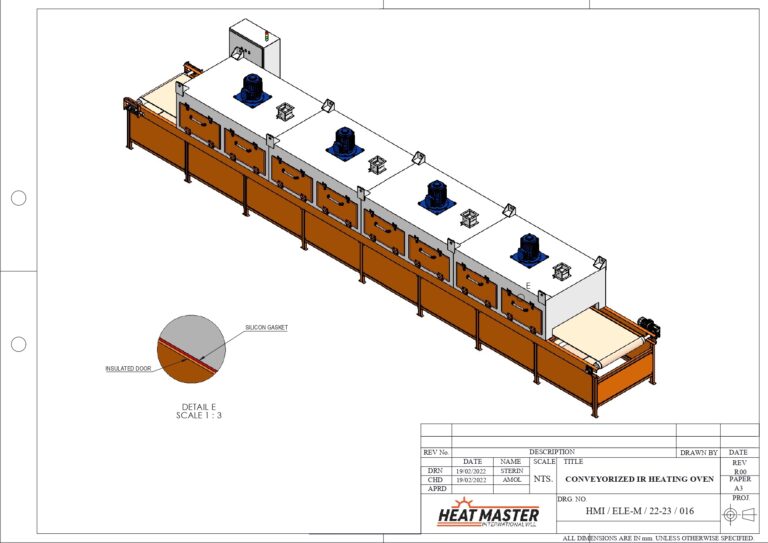

The engineering & design department of HMI has developed a wide variety of custom continuous ovens. Since each product requires a specific process, we offer a large range of solutions for conveying, controls, and their process designs.

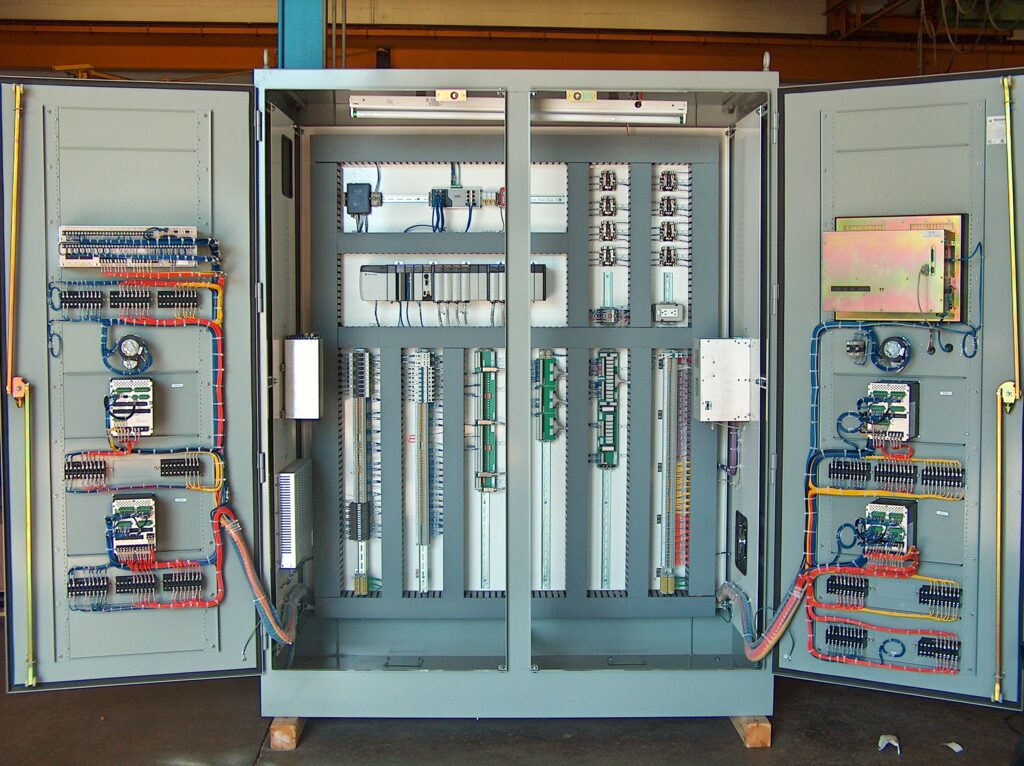

- Our custom conveyor ovens can provide temperature controls in multiple zones according to the different stages of the heating process of your product (desolvatation, temperature ramp, dwell time, cooling).

- Every zone has its own temperature management and its own extraction. Based on perfect knowledge of the products and a continuous control of the solvants evaporated, the extractions are optimized and the heating power adapted responding to security norms and excluding explosive risks.

- The fumes can be sent to an incinerator to eliminate VOC or to a heat exchanger to recover energy.

- As your product has unique features, the way it is heated will ensure process performance and a maximum of isotherm.

- The velocity and the orientation of the air flows are specific to each product. HMI offers the most suitable air flow styles (top to bottom, bottom to top, Transversal, Longitudinal, counter flow, multi flow.).

- The appropriately located pressure plenums will lead the air to the product through nozzles or adjustable whole area of heating and ensuring good temperature uniformity throughout the cycle.

Forced/refrigerated air cool down system, motorized dampers, humidity, pressure and vacuum controls, incineration of VOCs, exchangers for energy recovery, temperature recorders.

- Tunnel oven with flat belt conveyor (belt made of PTFE, steel, stainless steel, mesh, wire belt) for heat treatment

- Tunnel oven with chain conveyor (roller, accumulation, specific supports)

- Tunnel oven with belts (round, flat)

- Tunnel oven with motorized rollers, transfer by working-beams system

- Spiral oven – Automation solutions for loading and unloading

Our industrial conveyor ovens have a wide range of applications: polymerization, drying, tempering, annealing, vulcanization, curing, preheating, heat treatment, stabilization, aging

These are just a few of the Conveyorized Industrial Oven that your product line can incorporate while eradicating manual handling of the equipment –

Flat Belt conveyorized Oven –

Infrared Conveyorized oven –

Gas-fired Continuous oven –

Oil fired continuous oven-

Overhead conveyorized oven-

Belt Conveyor Oven –