Effluent Treatment Plants

We Design, Manufacture, Supply, Erection and Commissioning Effluent Treatment Plant (ETP) on a Turnkey basis for various types and natures of wastewaters, effluents that combine advanced physio-chemical treatment processes with a tertiary polishing system for the removal of organic, inorganic, oil, and grease, heavy metals & suspended solids.

Our methodology – We analyze the effluent samples for different effluent parameters as per nature and compositions, carry out the treatability studies by using different methods checking techno-commercial Feasibility, and then design treatment schemes, processes accordingly to suit the purpose and need.

Our ETP systems are very compact, tailor-made designs, portable required very less footprint to accommodate, energy-efficient. The up-gradation, modification in the existing ETP system is possible to achieve desired limiting standard laid down by the Pollution Control Board (PCB).

The Principle

The principle of operation of ETP is Physico-Chemical treatment followed by Polishing Treatments like –Sand Filtration, Activated Charcoal treatment (Adsorption), Ozonisation (Chemical Oxidation), Ultra Filtration (UF), Reverse Osmosis (RO), and evaporation (If required).

ETP Containerized Type

Capacity: 25 – 150 KLD, As per client Requirement

Technology: Physical / Chemical / Biological / filtration

Features:

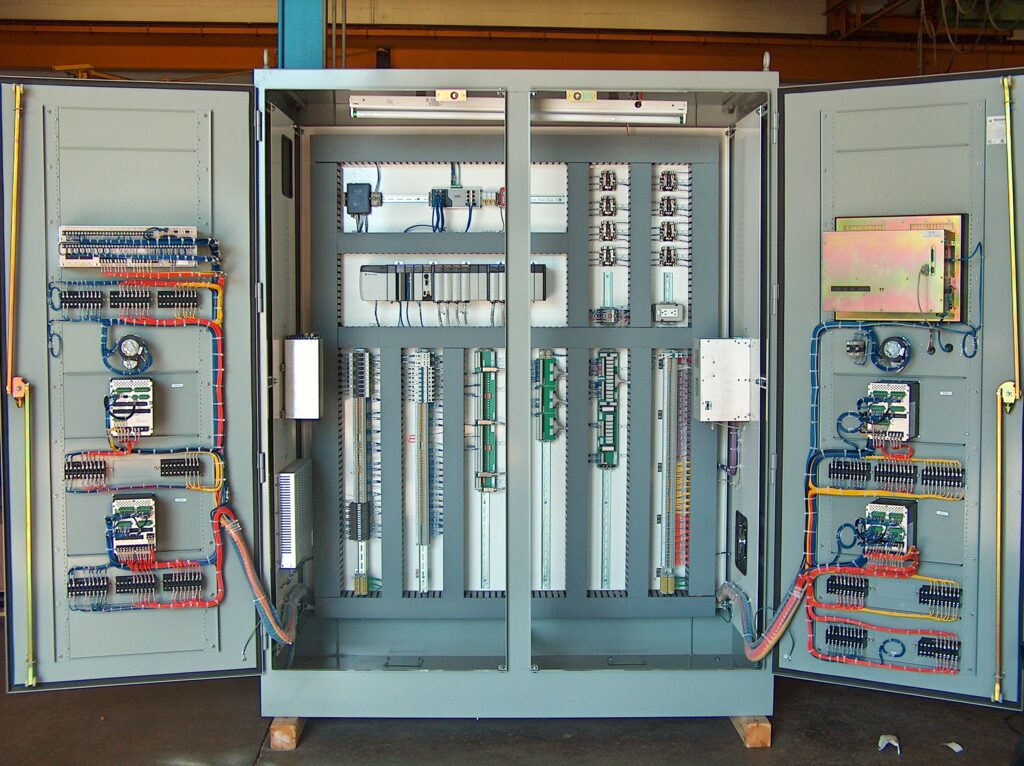

- Semi-automatic Operation.

- Required less space as compared to conventional design.

- Very Compact and Great aesthetic.

- Reduced Installation and commissioning time on site.

- Plug and play operation.

- Easy Dismantling and transportation.

- Made to order product.

- Civil Work – Collection Tank and Container Foundation.

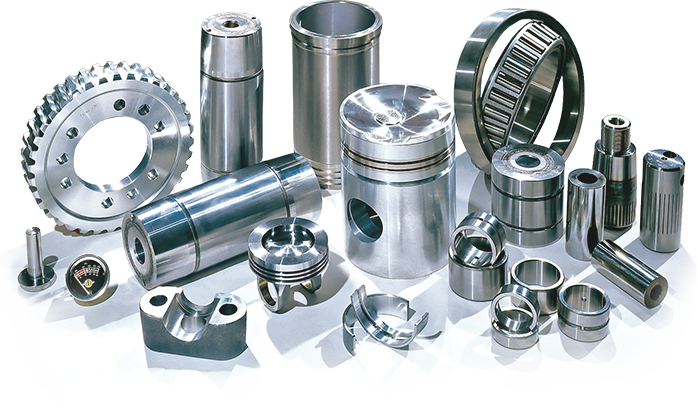

Typical Industries: Chemical, Pharmaceuticals, Automobiles, etc.

ETP – Continuous Type

Capacity: 15 to 1000 KLD, As per client Requirement

Technology: Physical / Chemical / Filtration

Features:

- Semi-automatic Operation.

- MS process tanks with internal FRP Coating

- Automatic chemical dosing with online pH monitoring.

- Advanced Filtration systems like UF, RO for Zero liquid discharge.

- Advanced sludge handling system.

- Compact design, required low foot print

- Better treated effluent quality as compare to conventional system.

- Corrosion free UPVC piping & FRP / Epoxy Lined MS tanks.

- Process Tanks – MS Fabricated / Civil (RCC)

Typical Industries: Automobile, Metal pre-treatment, Pharmaceuticals, Chemical, etc.