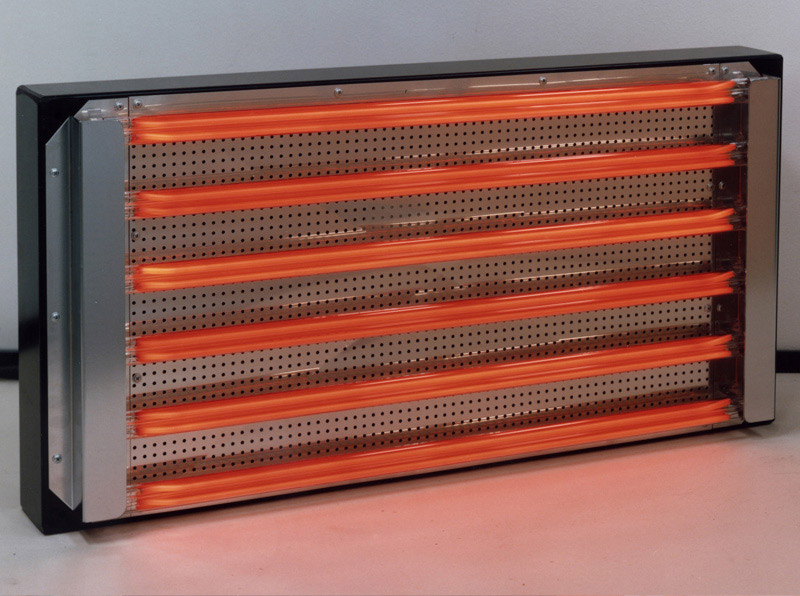

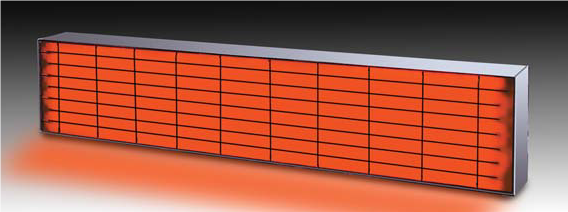

Infrared Heaters

Infrared lamps are basically heater lamps, working on the principle of infrared radiation heating. It is a direct and non-contact method for object heating where energy is transmitted by electromagnetic radiation. Depending on the absorption factor, the object can absorb up to 91% of the radiated energy, which gets transformed into heat. Normally, full efficiency is achieved within 1-3 seconds. With infrared heating systems, space requirements are reduced drastically.

Infrared Halogen Lamps are “bright emitters” as; part of the energy that is emitted is in the form of light. These lamps convert 84% of the electrical energy into Infrared radiation.

We, at Heat Master International, can manufacture these lamps in a variety of wattages, lengths, reflector coatings, and connections, as per your requirement.

The most efficient and flexible heat source –

- Instant on

- Up to 91% energy conversion

- Long life

- Robust design

- Dimmable

- Compact construction

- Ability to control

- Ability to direct

- PET bottle Manufacturing

- Comfort Heating

- Catering

- Automotive and Engineering Industry: Paint & putty baking, Powder Coating, Preheating Parts prior to shrink Fitting or Welding, Drying Washed Parts.

- Ceramic and Glass Industry: Baking, Sterilisation, Glaze Drying, TV tube Coat-Curing, Mirror Drying, Drying Washed Parts.

- Electrical Industry: Drying of Motors and Armatures, Baking Varnish on Motor Windings, Drying paint, Baking Enamel.

- Electronics Industry: Drying, Preheating, Curing and Solder Fusing of PC Board.

- Food Industry: Dehydrating Fruits & Vegetables, Food Processing, and Moisture Removal prior to Pulverising.

- Foundries: Drying of Moulds and Cores.

- Leather Industry: Curing Sprayed Shoe Leather Hides, Baking Finish on Leather Products.

- Plastic Industry: Preheating Plastics prior to Forming, Dehydrating Plastic Powders, and Curing Lamination & Adhesive Tapes.

- Pharmaceutical Industry: Bottle Sterilizing, Glue Drying on Surgical Tapes.

- Printing and Engraving: Drying Printing Ink, Setting Flux on Electrotype Castings, Silk Screen Drying and Curing.

- Pulp and Paper Industry: Drying of Tapes, Cones and Cylinders, Drying Paper Coating.

- Rubber Industry: Drying Rubber Laminations, Drying Paint on Hard Rubber Parts, and Curing Moulded Rubber.

- Textile Industry: Drying Fabre, Fabrics, Silvers, and Non-Woven, Heat Setting Nylon I Polyester, Binder Curing on Non-Woven Fabrics.

Type of Coating: / 98 White ceramic coating

Type of Burning Position: H ±5° to horizontal, V Vertical or universal burning

Note: All lamps are available with any combination of end contacts, coating any burning position. Special lead wires are available on request. Custom requirements on request possible.