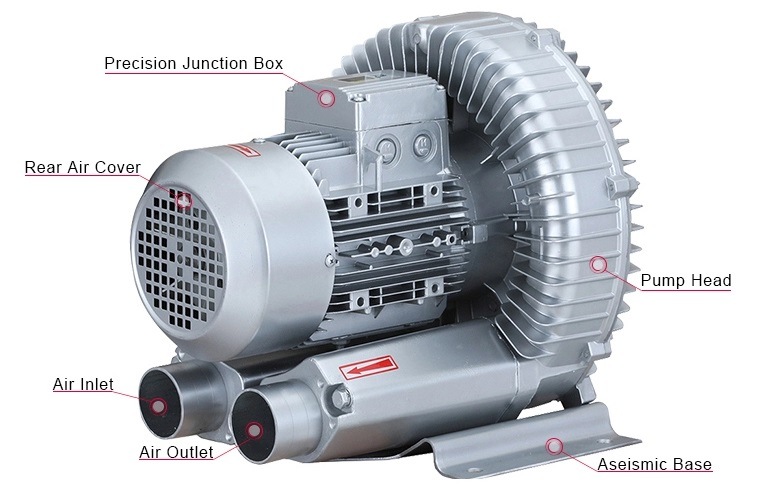

High-Pressure Blowers

High-Pressure blowers Lead the industry inefficient, stable performance and overall customer value. Pressure Blower is used in a variety of processes and environmental applications where low volumes and high pressures are required. Examples include pneumatic conveying, soil remediation, combustion, and numerous high pressures, gas handling systems.

HMI designs and constructs custom heavy-duty, durable High-Pressure Blowers using fully welded material, which provides a higher quality product compared to riveted construction. There are multiple options for materials of construction, including fiberglass, for various thermal, corrosive, particle-laden processes, and environmental conditions.

Types of High-Pressure Blowers –

High-Pressure Blower wheels have straight radial blades (positioned at 90-degree angles to the outside surface of the wheel hub) to keep them free of debris as the air and materials flow through the airstream.

Our High-Pressure Blowers include two primary wheel types – Open and Shrouded. Surge-less design enables them to provide consistent performance through variable flow (low to medium) and uniform pressure. The most appropriate wheel design is based on the volume and pressure combination of the air, along with the desired operating efficiency of the blower.

In addition to four pre-engineered models, our High-Pressure Blower line includes two hyper-custom models with several base designs. Capable of handling low particulate or vapor in high-pressure applications, our highly Custom High-Pressure Blowers:

- Meet unique customer requirements, space limitations, and equipment footprints to achieve API 673/560 requirements.

- Serve the widest range of applications, larger fans, and higher horsepower (1.5 – 1500 HP range) motors even when fixed speed is required.

- Accommodate consistent wheel width and optimize for low volume with greater efficiency at peak performance.

- Carry our industry-leading 3-Year Gold Standard Warranty. Precise, rugged and reliable, we build these fans to last.

- They also allow for a vast array of customization options, including:

→Gas-Tight Fans

→High-Temperature Fans

→Special Alloys/Abrasion & Corrosion-Resistant Materials

→Insulated Housing & Other Thermal Controls

→Special Coatings & Finishes

→Unique Sound Requirements

→Unique Space Requirements

→Skidded Process System

High-Pressure Fan Performance & Design Specs –

| Volume: up to 150,000 cfm |

| Pressure: up to 140” wg |

| Temperature: up to 1200°F |

| Static Efficiency: up to 78% |

| Drive: Belt & Direct |

Applications & Industries Served with Custom High-Pressure Blowers:

- Air Pollution Control

- Gas Treating/Cleaning (Sour Gas)

- Food Processing

- Glass-Blowing and Cooling

- Glass Manufacturing

- Petrochemical

- Petroleum

- Pharmaceutical

- Power Generation

- Pulp and Paper

- Steel Processing

- Vapor Recovery

- Water/Wastewater