Efficient Heat Exchangers for Industrial Excellence | Heatmaster International

Heat exchangers are essential components in industries that require precise temperature control. These devices allow the transfer of heat between two or more fluids, ensuring optimal energy use and enhancing system efficiency. At Heatmaster International, we specialize in providing top-tier heat exchangers designed to perform under the most demanding conditions. Whether you’re looking to cool, heat, or maintain stable temperatures, our heat exchanger provide the perfect solution for industries worldwide.

A heat exchanger is a device designed to efficiently transfer heat between two or more fluids. The fluids typically flow through separate channels, which allows heat to transfer from one fluid to another without mixing. Heat exchangers are crucial in industries such as HVAC, chemical processing, and power generation. They come in various designs, including:

- Plate Heat Exchanger: Compact and efficient, perfect for high-efficiency applications.

- Shell-and-Tube Heat Exchanger: Known for durability, ideal for large-scale industrial uses.

- Air-Cooled Heat Exchanger: Utilize ambient air for cooling, reducing water consumption.

Heatmaster International provides a wide variety of heat exchanger to meet the needs of your industrial process.

Applications of Heat Exchangers

Heat exchangers are used across multiple sectors, optimizing energy use and enhancing operational efficiency. Key applications include:

- Oil and Gas: Heat exchanger help in cooling fluids and managing temperature regulation in drilling and refining processes.

- HVAC Systems: Used for both heating and cooling in residential and commercial buildings.

- Food and Beverage: Heat exchanger are essential in pasteurization processes and maintaining product temperature.

- Power Generation: In power plants, heat exchanger play a crucial role in maintaining thermal regulation.

By using heat exchanger, industries can reduce energy consumption, lower operational costs, and enhance overall productivity.

Benefits of Using Heat Exchangers

Investing in quality heat exchangers can lead to numerous operational benefits. These include:

- Energy Efficiency: Heat exchanger optimize heat transfer, reducing energy consumption and lowering costs.

- Cost Savings: By improving thermal efficiency, heat exchanger contribute to reduced energy bills.

- Environmental Benefits: Lower energy usage results in fewer emissions, supporting sustainability efforts.

- Enhanced Durability: Built to withstand high temperatures and pressures, heat exchanger offer long-lasting, reliable performance.

At Heatmaster International, our heat exchangers are engineered to deliver exceptional value by combining energy savings and robust performance.

Types of Heat Exchangers Offered by Heatmaster International

At Heatmaster International, we offer a broad selection of heat exchanger to suit a wide range of industrial applications:

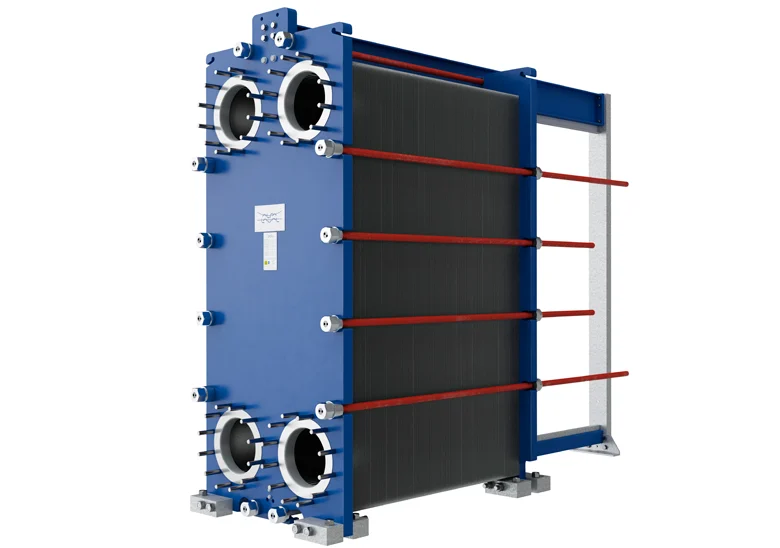

Plate Heat Exchanger

Plate heat exchanger are compact, highly efficient units designed to maximize heat transfer in limited spaces. These exchangers consist of a series of thin plates stacked together to form multiple channels, through which the fluids flow. The arrangement allows for a large surface area in a small footprint, ensuring efficient heat transfer between the fluids. Plate heat exchanger are commonly used in applications such as HVAC systems, food processing, and pharmaceuticals, where space and energy efficiency are critical.

Shell-and-Tube Heat Exchangers

Shell-and-tube heat exchanger feature a robust design suitable for high-pressure and high-temperature applications. They consist of a series of tubes enclosed within a cylindrical shell. One fluid flows through the tubes, while the other circulates around the tubes inside the shell. This design makes them ideal for handling large volumes of fluids in demanding industrial processes. Shell-and-tube heat exchanger are widely used in industries such as oil and gas, power generation, and chemical processing.

Air-Cooled Heat Exchanger

Air-cooled heat exchanger rely on ambient air to dissipate heat from fluids. These exchangers typically feature a series of finned tubes and fans that draw air over the tube surfaces, transferring heat from the fluid to the air. This makes them an ideal solution for environments where water availability is limited or water conservation is necessary. Air-cooled heat exchangers are commonly used in industries such as mining, power plants, and HVAC systems.

Each of our heat exchanger is engineered for maximum heat transfer efficiency, ensuring your systems run smoothly and cost-effectively. To learn more, visit our heat exchanger product page.

How to Choose the Right Heat Exchanger

Selecting the right heat exchanger is vital for achieving the best performance and efficiency. Consider the following when choosing:

- Application Needs: What temperature and pressure conditions are required for your process?

- Material Compatibility: Ensure the heat exchanger materials are compatible with the fluids being used.

- Heat Transfer Efficiency: Look for models that offer high thermal conductivity for superior energy transfer.

- Maintenance Requirements: Choose heat exchanger that are easy to maintain and service.

At Heatmaster International, we provide expert advice to help you choose the ideal heat exchanger for your application. Contact us for a consultation or explore our product selection.

Maintenance and Care of Heat Exchanger

To maintain optimal performance, regular care and maintenance of your heat exchanger are essential. Key maintenance tips include:

- Routine Inspections: Regularly inspect for leaks, corrosion, and damage.

- Cleaning: Periodically clean the heat exchanger to prevent scale buildup and fouling.

- Fluid Replacement: Replace fluids as necessary to maintain efficient heat transfer.

For expert maintenance services, contact Heatmaster International and let us ensure the longevity of your heat exchanger.

FAQs About Heat Exchanger

What is the difference between plate and shell-and-tube heat exchangers?

Can air-cooled heat exchangers be used in all environments?

How do I determine the right type of heat exchanger for my application?

How often do heat exchangers need to be maintained?

Contact Heatmaster International

Looking to learn more about heat exchanger or need expert guidance? Contact Heatmaster International today! Our team of professionals is ready to help you select the right heat exchanger for your needs.

- Contact Us: +973 38456667

- Visit Us: Unit No m6, Building No . 2171 Road No. 3632 , Al Ma’ameer 636 Kingdom of Bahrain

- Request a Quote: marketing@heatmasterint.com