Applications of Powder Coating Ovens

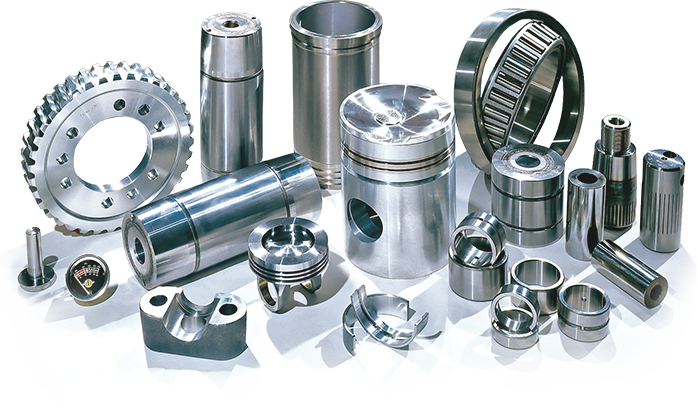

Automotive Industry: Used to coat vehicle frames, accessories, and parts to improve strength and appearance while offering corrosion protection.

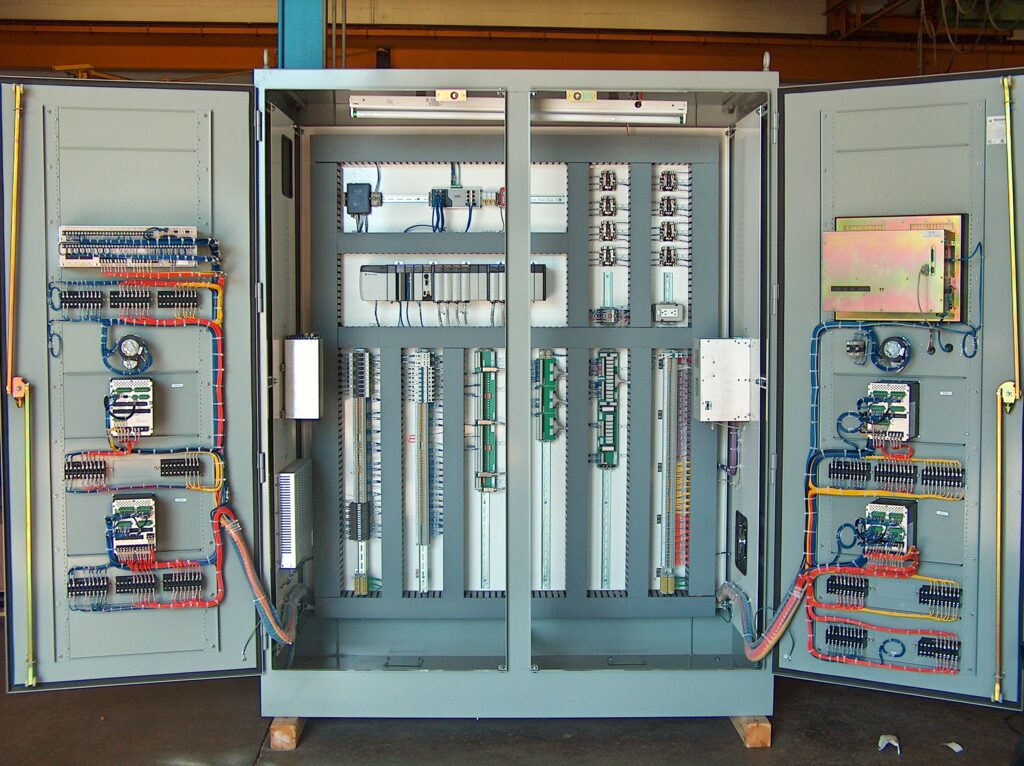

Metal fabrication: Perfect for applying a smooth and uniform finish to a variety of metal components, such as enclosures, frames, and brackets.

Home Appliances: Often used to improve appearance and resistance to wear and chemicals, coatings are applied to appliances such as microwaves, washing machines, and refrigerators.

Furniture Manufacturing: Used to apply a durable finish to metal furniture that can endure frequent usage and exposure to the elements.

Architectural Elements: Applied to window frames, railings, and other architectural elements to improve their longevity and visual appeal.

Cycle & Motorbike Parts: Enhances performance and longevity by applying a weather-resistant coating on frames, wheels, and accessories.

Key Features of Heatmaster Powder Coating Ovens

even Heating: Equipped with state-of-the-art circulation and heating technology to provide consistent curing, prevent hotspots, and ensure uniform dispersion of heat.

Temperature Control: Precise digital temperature controls allow for accurate temperature setup and monitoring, which is crucial for achieving the proper finish in the oven.

Robust Construction: The use of high-quality materials that can withstand the rigorous coating process ensures longevity and dependability.

Energy efficiency: Designed to minimize energy use without compromising functionality in order to save operating costs.

Ventilation Systems: Integrated exhaust systems help regulate the oven’s air quality by getting rid of surplus powder and keeping the workspace safe.

Benefits of Heatmaster Powder Coating Ovens

Consistent Finish: Powder coatings cure evenly thanks to uniform heating, leaving all surfaces with a high-quality, smooth finish.

Enhanced Efficiency: The coating process is optimized by quick heat-up periods and accurate temperature management, which shortens cycle durations and boosts output.

Energy Savings: These ovens’ energy-efficient design reduces electricity usage, which lowers operating expenses.

Durability: Heatmaster ovens are made of sturdy materials and are made to endure the demands of industrial use, guaranteeing long-lasting performance.

How to Choose the Right Powder Coating Oven

Dimensions: Make sure the oven is big enough to fit the pieces you plan to coat.

Production Volume: Take into account how much product you’ll need to process; high-volume operations can require bigger ovens.

2. Range of Temperature

Maximum Temperature: Choose an oven that can achieve the curing temperatures needed for your particular powder coating materials.

3. Heating Technique

Gas versus Electricity: Choose between gas and electric ovens depending on the running expenses and infrastructure of your company. In general, electric ovens provide accurate temperature control.

4. Dispersion of Heat

Even Heating: Seek for ovens that have sophisticated circulation systems to guarantee even heating throughout, avoid hotspots, and accomplish even curing.