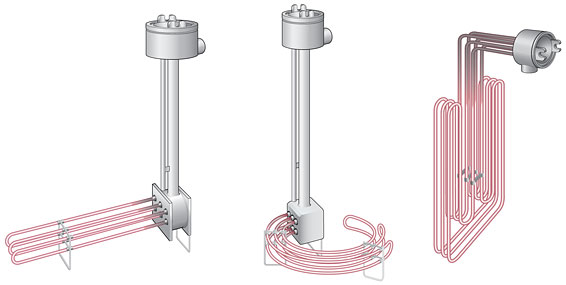

Over The Side Immersion Heaters

Over-the-side electric immersion heaters are widely used in the metal finishing industry in plating tanks due to their convenience at a lesser cost when compared to a Bottom or L-shaped Electric Immersion Heater. Another advantage is the chemical solution doesn’t need to be drained to change heaters like with screw plug or flanged immersion heaters. The side Immersion Heaters are typically used in smaller tanks (or in larger tanks with a steering device for temperature uniformity) with lower temperatures and for deep tanks as used in the chrome plating industry. We make immersion heaters for up to 30ft deep tanks.

These industrial immersion heaters are used in tanks where through-the-wall heaters cannot be installed, portability is required, or where heaters must be removed without emptying the tank. They are suitable for freeze protection, or heating viscous materials (example: passivating tanks). L-shaped heaters have the advantage is better heat distribution. With the heating elements on the bottom, there is less chance of exposure to air which will cause premature burn-out.

NH Industrial Heating Systems’ Over-the-side Immersion Heaters incorporate an all-welded junction box made of the same material as the heater sheath. This ensures a liquid tide seal on the body and provides great physical protection. Make sure the chemical solution is above the minimum solution level bracket welded to the sheath.

- Industry standard or custom designs

- Robust, light-weight construction

- Re-compacted element bends ensuring insulation integrity

- Element materials: Steel, copper, incoloy 800 and 840, 304 and 316 stainless steel

- C-UL heater element recognition to 600VAC available

- 4” sludge legs keep elements elevated to provide optimal heating

- Water heating

- Solvents

- Freeze protection

- Salts

- Viscous oils

- Caustic solutions

- Storage tanks

- Paraffin

- Degreasing tanks